UV Curing Lamps and Systems Applications | Benford UV

WHY INSTALL A BENFORD UV CURING SYSTEM ONTO YOUR SHEETFED PRINTING PRESS ?

Benford are specialists in UV retrofitting, installing UV curing systems onto new and used offset printing presses all over the world. By converting your machine to UV curing with our high-tech, ultra-reliable and eco-friendly systems you will enable printing to several different substrates, such as paper, carton, metallised or foil-coated cartons, films and plastics such as PP, PE, PVC and PET. UV technology opens a wide range of new applications and opportunities for offset printers, like packaging, high-end commercial printing with UV effects, labelling, currency printing, credit cards etc. Benford also offers comprehensive support from our team of highly trained engineers and UV consultants, guaranteeing quick and professional installation, commissioning and training to fully support the systems on site.

UV CURING LAMP SYSTEM COMPATABILITY

UV CURING LAMPS FOR WIDE WEB PRESSES

Web Offset Printing is a form of printing in which a continuous reel of paper is fed through the printing press. By installing a UV curing system on a wide web press, jobs dry instantly allowing production to be sped up.

Our team has experience in UV retrofitting different models of wide web presses with different UV curing lamp technology. We have extensive experience installing UV curing lamps to Goss, Heidelberg, Timpson and Hantscho printing presses, with different widths from 36” to 60”, for example.

Some advantages that UV curing offers:

- Further processing can be carried out immediately

- Shorter curing times, reduced downtimes

- Cost-effective option

- Colour quality is brighter and sharper

Available in widths from 250mm/10” to 650mm/26

NARROW WEB LED UV SYSTEMS

This new technology offers:

- Faster production

- Low operating costs

- Instant on-off and no warming time

- Ozone free and no mercury

- Consistent print results

- Deep cure for metalics, white and black inks

OUTPUT CONTROL

Energy output will adapt automatically to the printing speed ensuring perfect curing of inks.

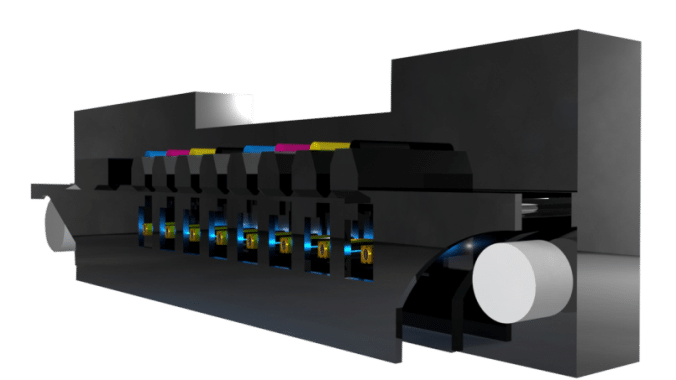

COMPACT DESIGN

Ultra-compact cassette that fits onto any machine. Electrical cabinet designed to take minimal floor space.

QUARTZ BARRIER

The design incorporates a quartz shield barrier that protects the LED chips.

TEMPERATURE AND CURRENT CONTROL

Monitoring system for temperature and current outputs on LED chips.